What are Explosion Proof Ejectors?

Combustion occurs when a combustible material is decomposed exothermically when combined with a supply of oxygen. An explosion may occur with the combination of combustible material, oxygen and a source of ignition. An explosion requires all three to be present, or an explosion will not occur.

Common sources of ignition include sparks created by friction, impact or abrasion. Another source would be arcs caused by a short circuit during switching operations. Finally hot surfaces may cause ignition.

In the case of gases, the ratio of the concentration determines whether an explosion is possible. The mixture of fuel to air will only be ignited if the concentration is between the lower (LEL) and upper (UEL) explosive limits. In the case of diesel fuel these limits are .6 to 6.5% respectively. In the case of gasoline these limits are .6 to 8% respectively.

Submersible sewage or sump pumps are often used in pits located in parking garages in which runoff would contain fuels which may have leaked from parked vehicles. This can lead to an explosive atmosphere in or around the pit. Explosion proof pumps and control panels are desirable in these areas. Pumps can be offered with bronze non-sparking materials to alleviate ignition from casual contact. (Figure 1) Explosion proof motors are offered in these pumps as well. However panels must be constructed to avoid an ignition source. (Figure 2)

How Are Panels Intrinsically Safe?

Explosion proof control panels are designed to meet UL 698A/NEC 504 Class I C&D (Gases) and Class II E,F&G (Dust). Intrinsic Safety (IS) is defined as a circuit which is designed to limit the voltage and current such that no spark or thermal effect can cause a potentially explosive atmosphere to ignite.

The voltage is limited to keep a spark below the ignition energy of the surrounding gas. The thermal effect (hot surfaces) is prevented by limiting the maximum current flow through the circuit.

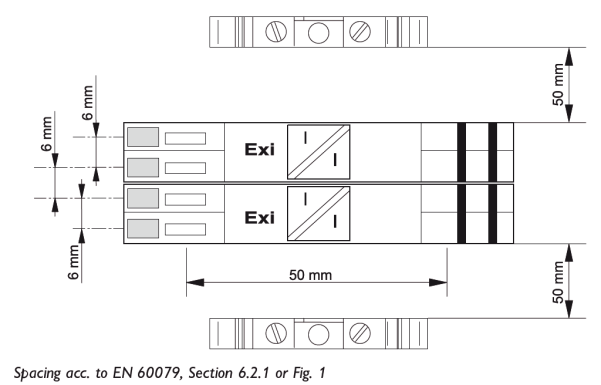

The maximum permissible energy allowed is defined per IEC 60079-11 and NEC 500. In addition, the air distances between terminal blocks must be .25 inches (6 mm) minimum to avoid arcing. The distance between intrinsically safe and non-intrinsically safe circuits must be 1.968 Inches (50mm) minimum. (Figure 3)