What is a Pressure Regulating Valve (PRV)?

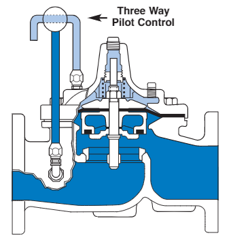

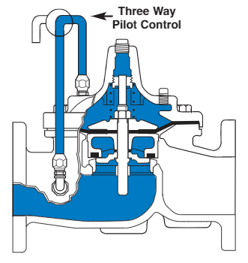

Pressure regulating valves (PRV) are a self-regulating valve designed to provide a set pressure to a piping branch in a building. The booster system provided the building with its system pressure which may damage the fixtures within the building. The pressure reducing valve reduces the valve output pressure via a pilot control. The pilot control is set to allow a portion of the inlet pressure behind the valves diaphragm to allow a portion of the inlet pressure to pass to the outlet of the valve. If the outlet pressure drops the valve opens slightly to allow more pressure. If the outlet pressure rises, the valve closes slightly to prevent more pressure from passing through the valve outlet. The valve outlet pressure will fluctuate based on the amount of flow consumed by the downstream fixtures.

Do I need to maintain a PRV?

Pressure reducing valves (PRV) are relatively simple hydraulic devices, but regular maintenance is recommended. A PRV maintenance program includes the following critical activities:

- Check for damaged pilot controls

- Clean the inlet strainer and pilot strainer

- Clean or replace clogged pilot fittings

- Inspect the main diaphragm for leakage

- Vent all air from the pilot control lines

The pilot control is the brains of the PRV. If the pilot control is damaged or leaking it will cause the PRV to deliver higher or lower pressure than is required by the building and may cause downstream fitting failure. Ensuring the pilot is working properly is critical to reliable operation. The pilot and the valve typically are provided with strainers to prevent collection and buildup of unwanted debris. Sediment, rocks or even metal debris can damage the valve if they collect around the valve seat. If sediment collects at the strainer, it can restrict flow and cause inaccurate pressure downstream. Strainers should be checked and cleaned regularly. If strainers are not used, then clogged fittings can occur. If fittings (typically pilot control elbows) are clogged, then hydraulic pressure is not delivered behind the diaphragm and the PRV will deliver more pressure than desired. All fittings should be checked for clogs and be cleaned or replaced. Once the main diaphragm is checked for leaks all air should be bled from the control lines to insure accurate function.