What is an Electro-Adsorptive Filter?

The word adsorption is defined by Merriam-Webster® as the adhesion in an extremely thin layer of molecules (as of gasses, solutes, or liquids) to surfaces of solid bodies or liquids with which they are in contact.

Typically filtration of viruses, bacteria, and pathogens is achieved by placing a media within a contaminated flow stream with very small pores to restrict passage through the membrane. The contaminants collect on the surface of the membrane which is removed and replaced as pressure increases and flow decreases. This approach achieves the desired removal, but requires very high pressure to remove these pathogens.

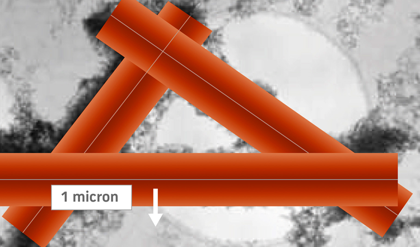

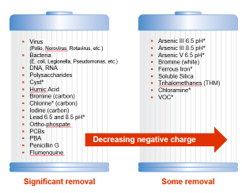

Fundamental research in filtration has yielded an improved technology known as “electro-adsorptive filtration”. The filter media is designed with larger pored media which is positively charged. Dangerous contaminants are, very often, negatively charged(Figure 2). Ionic attraction causes the positively charged filter elements to capture dangerous negatively charged contaminants at higher flow rates than conventional filtration.

Adsorptive filters allow more flow while achieving 4 and 6 log reduction of viruses, cycts and bacteria without additional dangerous chemicals, or a high differential pressure. This makes electro-adsorptive filters more efficient and more reliable than most alternatives.

Key to Success

Electro-adsorptive filtration is best used after pre-filtration to remove larger solids in the flow stream. Typically solids are removed down to 10 micron prior to electro-adsorptive filtration. It is often used as a means for final filtration to polish potable water, for rain water harvesting, and when bio fouling of storage tanks, cooling towers or reverse osmosis filtration units occurs.

Filters can be contained in stainless steel vessels which are designed to meet ASME Section VIII Div. 1, yet allow easy removal and replacement of filters when the pressure differential between the outlet and inlet reaches the manufacturers recommended differential. It is critical the vessel be designed to accommodate the pressure provided to the filter. The vessel shown in (Figure 3) is designed to operate at 150 Psig Maximum Allowable Working Pressure.

Potable water filtration requires a stainless steel vessel as shown in (Figure 3).