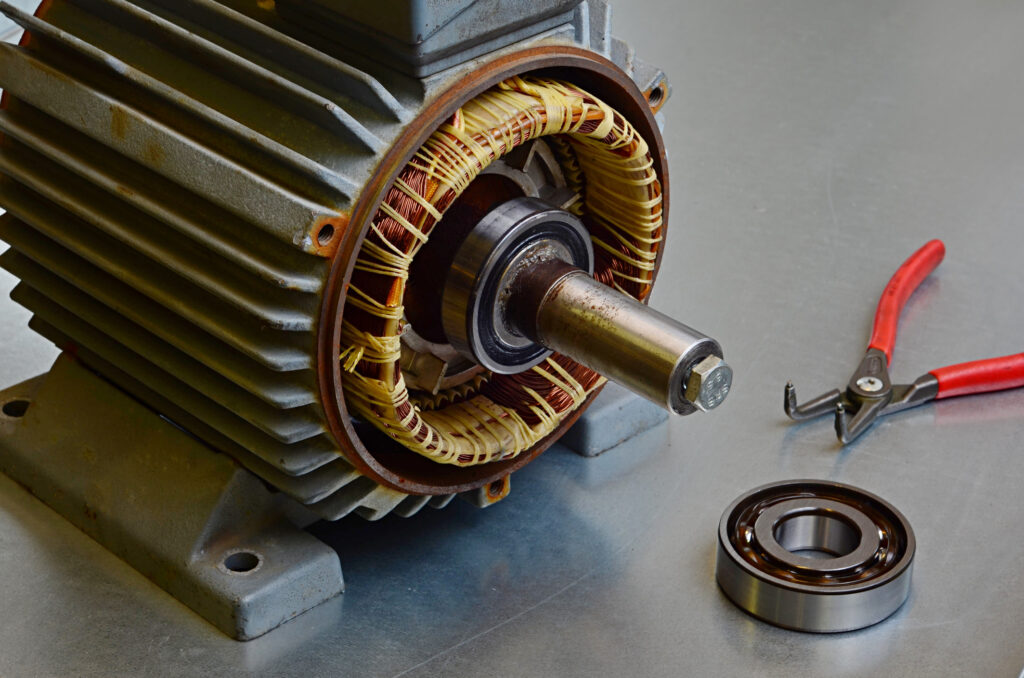

Our motor repair service begins with a complete detailed inspection and testing on all equipment. A motor repair service consists of disassembly and cleaning of the motor, assessing for damage and repair or replacement of parts. Then the motor is reassembled and depending upon the motor’s construction and condition, rewinding of the motor may be necessary. Our technician records these steps on film so we can discuss the repair with you and show the damage or repairs that need to be done.

Delta Electric Motor uses class H winding materials and inverter rated magnet wire when repairing motors. Why? To ensure a long lasting reliable repair.

In addition, when bearings are needed only the highest standard of quality bearings are used to ensure a proper fix and improve the overall performance of your equipment.

If after an evaluation of the motor it is decided that the motor is at end of life, Delta Electric Motors has the buying power and experience to find the right motor for replacement.

| 1 & 3 Phase Motors | AD/DC Motors | Brake Motors |

| Brush Shifting | DC Servo | Fractional to 500 HP motors |

| Gear Motors | NEMA and Metric Frame motors | Spindle |

| Stainless Steele | Wash Down |

| Armatures | Brakes | Field |

| Forms & Randow Wound | Inverter Duty Wire | Phase Paper & Separators |

| Rotors | Stators |

Delta uses Inverter Duty™ wire when rewinding a motor which has a higher resistance to voltage spikes produced by all VFDs.

| Blower Wheel Repairs | Dynamic Balancing | Fabrication |

| Machining | Plating and finishing | Sandblasting |

| Shaft Repairs | Spray Welding | Welding |

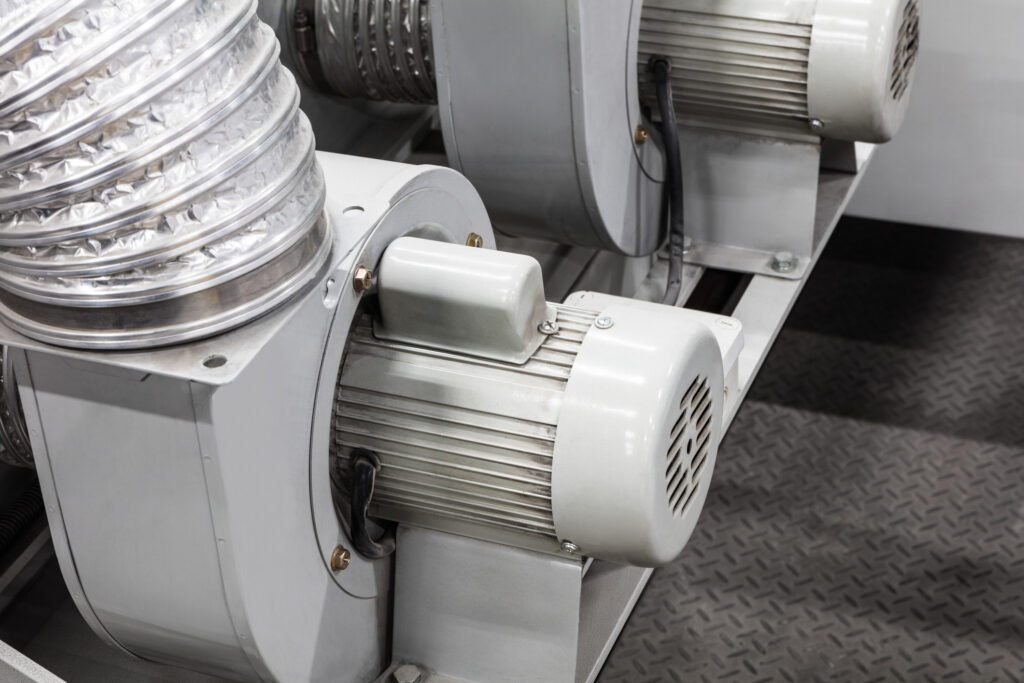

| Vacuum/Pressure/Comb | Fan |

|

|

|

|

|

Blowers |

|

|

|

Blower Wheels |

|

Exhaust Fans |

|

| Condenser Fan Motors | Evaporative Cooler Motors |

| Pedestal Fan Motors | Cooling Towers |

| Chillers | OEM Fan & Blower Motor Replacement |

| Hot & Cold Water Circulating |

Choose Gustavo for high-quality, comprehensive service and solutions.