What are Long Coupled Pumps?

Long coupled horizontally mounted pumps are defined as pumps which are driven by a separately mounted driver. A driver is most often an electric motor but can be an internal combustion engine. The driver shaft is “coupled” to the pump (driven) shaft to provide the energy to move the fluid. There are various types of couplings which all have their strengths and weaknesses but “allow” a small amount of mis-alignment between the driver shaft and the driven shaft.

However, mis-alignment of the driver shaft to the driven shaft can seriously compromise the reliability of the driven equipment. Specifically, mis-alignment causes vibration damage to precision bearings, mechanical seals, and the coupling itself resulting in shorter equipment life and forcing expensive and untimely repairs.

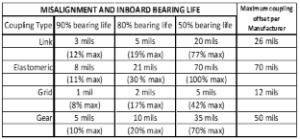

Equipment manufacturers publish “Maximum” offset (misalignment) dimensions but may not indicate the affect on reliability. Reliability engineers have studied the data and revealed the substantial cost of mis-alignment.

Customers may feel the manufacturer aligns the equipment prior to shipping, but shipping and handling can degrade alignment substantially. A “final alignment” is critical prior to equipment startup and should be done annually due to system upsets or pipe stresses. Mechanical work in the area may also deteriorate alignment.

Why Use Laser Alignment?

Alignment of a Driver to a Driven shaft can be done with a variety of technologies, however rotating equipment technicians have adopted “Laser Alignment” tools (figure 2) to align two shafts while in the operating state. The operating state is defined as the speed and operating temperature of the driver to the driven.

Hot liquid flowing through a pump housing can cause substantial thermal growth which results in the centerline of the driven shaft to “rise” as the metal is heated by hot liquid. Laser alignment tools allow compensation to align for the operating state of the equipment.

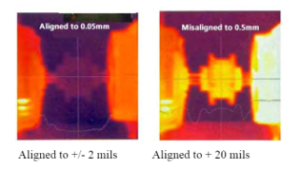

The affect of mis-alignment can be seen using thermographic imagery (figure 3). This occurs as metal surfaces are forced to contact and rub against each other to compensate for mis-aligned shafts. Annual alignment checks and tracking are the key to reliable Long Coupled equipment.