What is Hunters Curve?

Roy B Hunter issued “Methods of Estimating Loads in Plumbing Systems” developed for the National Bureau of Standards on December 16, 1940.

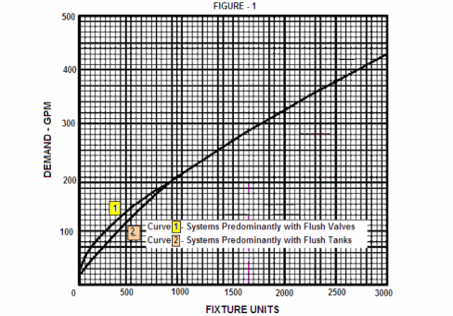

The question Mr. Hunter sought to answer was given n (identical) fixtures in a system, each opened once in (T) seconds on average, and opened for an average duration of (t) seconds, what is the probability that (k) fixtures will be open simultaneously at any given time? Mr. Hunter used a Binomial distribution model which considered pulse intensity (q), duration (t) and frequency (T). He solved for a 99% chance the fixtures would be in use.

As a result he developed the idea of a Fixture Unit (FU). A fixture unit is an arbitrary comparative dimensionless value assigned to a plumbing fixture which represents the probable flow which will occur. Each fixture is assigned a value which can be tallied and converted to demand in GPM.

Sanitary discharge and water demand fixture units are different, so the designation for drainage fixture units is DFU, while the designation for potable water fixture units if WFU.

Why Use “Modified” Hunters Curve?

Today’s toilets are designed to use approximately 1.28 gallons per flush whereas in 1940 when Hunters curve was developed it was not uncommon for toilets to 5 gallons or more per flush. The difference in the fixture flow has resulted in substantially less water usage per person.

Conversely the modern apartment may have two or three bathrooms whereas buildings of the past may have only offered a single bathroom per apartment. Increasing the number of fixtures per person in a living space reduces the probability of their simultaneous used.

These two factors have prompted industry groups and manufacturers to offer Modified Hunters Curves which build upon the original work, but consider empirical data to reflect more realistic Fixture Unit values.

Over sizing of supply systems can lead to pumps operating at or near shutoff causing vibration, bearing strain and possibly lead to premature seal failure. If variable frequency drives (VFD) are used then the drives can be forced to run at lower frequencies. Manufacturers do not recommend operating below 50% as pump efficiencies decline, and recirculation increases at lower speeds.