What is a Motor Service Factor?

Motor Service Factor — Service factor (SF) is an indication of how much overload a motor can withstand when operating normally within the correct voltage tolerances. For example, the standard SF for open drip-proof (ODP) motors is 1.15. This means that a 10-hp motor with a 1.15 SF could provide 11.5 hp when required for short-term use. Some fractional horsepower motors have higher service factors, such as 1.25, 1.35, and even 1.50. In general, it’s not a good practice to size motors to operate continuously above rated load in the service factor area. Motors may not provide adequate starting and pull-out torques, and incorrect starter/overload sizing is possible.

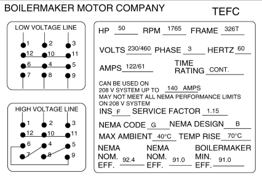

Traditionally, totally enclosed fan cooled (TEFC) motors had an SF of 1.0, but most manufacturers now offer TEFC motors with service factors of 1.15, the same as on ODP motors. Most hazardous location motors are made with an SF of 1.0, but some specialized units are available for Class I applications with a service factor of 1.15.

What is a Voltage Tolerance?

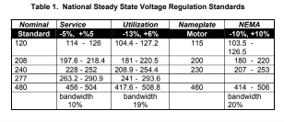

ANSI standard C84.1 delineates voltage regulation. Its title is American National Standard for Electric Power Systems and Equipment – Voltage Ratings at 60 Hertz (Cycles per minute). (Refer to Figure 1) The original version published in 1954 was a combination of two standards, one from the Edison Electric Institute and the second from the National Electrical Manufacturers Association (NEMA). The standard establishes nominal voltage ratings for utilities to regulate power service delivery and establishes operating tolerances at the point of use. These limits apply to sustained voltage and are not relevant for momentary voltage excursions.

For example, 480V is referred to as the “Distribution Voltage” and 460V is referred to as the “Utilization Voltage”. 460V was chosen by NEMA as the Utilization Voltage for motors because prior to any universal standards, some motors were designed for 440V, some for 460V and some for 480V. You can still see that on old motor nameplates. 460V was the “compromise” that allowed manufacturers to unify their nameplate information without necessarily changing their design.