What is a Self Cleaning Filter?

A self cleaning filter is designed to clean the filtration element when clogging occurs.

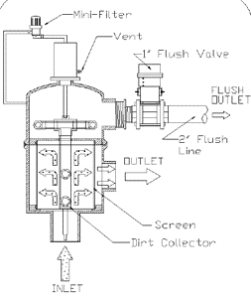

A self cleaning filter allows contaminated water to enter the filter inlet (figure 1) and travel through a fine mesh stainless cylindrical screen. Small contaminants cannot pass through the screen, so they collect on the surface. Clean water then exits through the outlet of the filter.

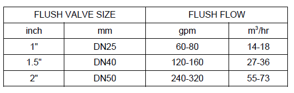

When the fine mesh screen becomes contaminated, a pressure differential is sensed causing the automatic controller to open the flush valve. When the flush valve opens, an atmospheric pressure path is established, causing the clean water to reverse flow at the point of suction across the fine mesh screen. This process removes contaminants from the screen, sending the dirty water through the nozzles and the dirt collector mechanism and out the flush valve.

The water passing through the hydraulic motor creates an axial rotation of the dirt collector. This movement, combined with linear advancement, allows the dirt collector to vacuum the entire screen element.

The cleaning cycle takes about 4-6 seconds. If the filter is designed without a piston, the cleaning cycle takes about 2-4 seconds. During the flush cycle, the filtration process and main flow continues uninterrupted.

Keys to Success

The filter requires a minimum pressure of 40 PSI at the inlet during the cleaning cycle for effective cleaning. It is critical the combined flow of cleaning and filtration provide a minimum pressure of 40 Psig above the downstream pressure.

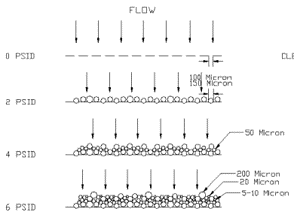

The second issue to consider is the number, type and size of debris contained in the flow stream. The fine mesh screen must be selected to allow the desired flow by specifying the required area of the screen, but also retain solids in the target size. If the size of solids is much larger than the screen mesh, then constant back flushing will occur. If the size of solids is much smaller than the screen mesh, then the filter will be ineffective. To avoid this issue a water test is recommended prior to filter selection to assist in selecting the proper mesh size.

The third issue to consider is the required flow rate. If the flow rate required is 120 gpm, and the available filters are 100 gpm and 150 gpm, then select the 150 gpm filter to avoid issues.