What is a Thermal Relief Valve?

Thermal relief valves, also known as pump protectors, are used to alleviate heat in the pump casing to protect the mechanical seal or packing used in the pump. They are offered in a variety of materials including plastic, brass and 300 series stainless steel. The thermal relief valve is typically mounted in the pump casing as close to the impeller as possible.

Thermal relief valves are described under US patent number 5018665 dated May 28, 1991. The patent describes the use of a “wax element actuator” which is a device which transforms changes in temperature into movement of an actuating pin.

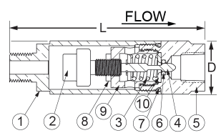

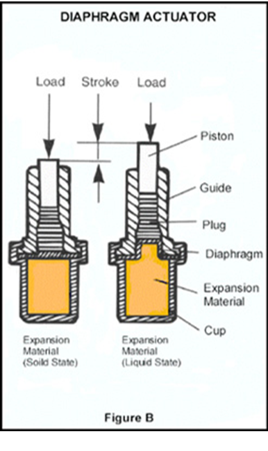

Many manufacturers offer thermal relief valves. Figure 2 provides a cross sectional view of a thermal relief valve. The wax element actuator is Figure 2 item 2. Once hot fluid surrounds item 2, the piston (item 4) extends a set length opening the valve and allowing flow. Flow will continue until cooler fluid surrounds item 2. Figure 3 depicts this phenomenon more accurately. Inside item 2 a expansion material (wax) is contained. The material will change phase from a solid to a liquid once hot fluid surrounds item 2 extending the actuator.

Thermal relief valves can be designed to actuate at a variety of temperatures.

Why Use a Thermal Relief Valve?

Pumps used in booster systems may operate while allowing very little flow due to so called “leak loads”. Leak loads occur from small leaks in the plumbing system which forces the booster pumps to run unless an expansion tank is used. Expansion tanks are used to avoid inefficient short cycling of booster pumps.

If the pump runs at very low flow the energy the motor is imparting to the fluid is expressed as heat and may cause seal failure. To avoid this issue many booster manufacturers install thermal relief valves in the pump casing to detect the fluid temperature. Once the fluid temperature in the casing reaches a pre-set limit the valve opens allowing flow. Once flow is enabled the fluid temperature declines. This safeguard protects the pump and provides a more reliable booster system. Typically thermal relief valves open at ~140 F and close at ~130 F when used in booster systems. Thermal relief valves should be piped in series to the nearest drain.