Why Use Double Walled Basins?

Submersible sewage pumps can be used to remove aggressive waste which may contain volatile chemicals detrimental to the environment. Submersible pumps are often provided in stainless steel to provide resistance to chemical attack from the collected fluids.

However the aggressive nature of the fluids makes a second level of containment desirable. Manufacturers offer “double walled” basin’s which provide a chamber which can be monitored for leakage. (See figure 2). Double walled basins consist of two basins described as an inner basin and an outer basin. The inner basin is mounted concentric to the outer basin. The inner basin’s smaller diameter mounted inside the larger outer basin establishes a chamber to collect and monitor for leakage. Generally these basins are designed to be acid resistant to avoid chemical attack.

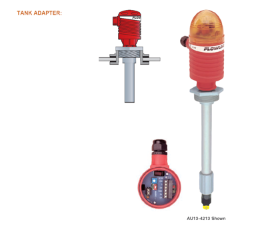

A Liquid Level Switch (See figure 1) is mounted on the basin cover to monitor leakage. The switch, when detecting leakage, sends a signal to activate an alarm to advise the user of the leakage from the inner basin. Steps can then be taken to mitigate the leakage to the surrounding area. The level switch can be wired to an adjacent wall area via a junction box mounted on the cover. The level switch may be offered with an optional strobe flash alarm (See figure 1) to bring attention to the issue. Often these switches are capable of being wired to control the submersible pump and solenoid valves to control inflow to the pit to prevent further leakage. Switches are offered in various mounting configurations including NPT, NPT Socket, NPT Bulkhead, ANSI flange and side mounting brackets.

Double Walled Basin Covers

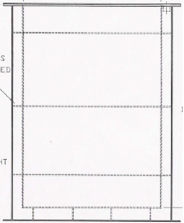

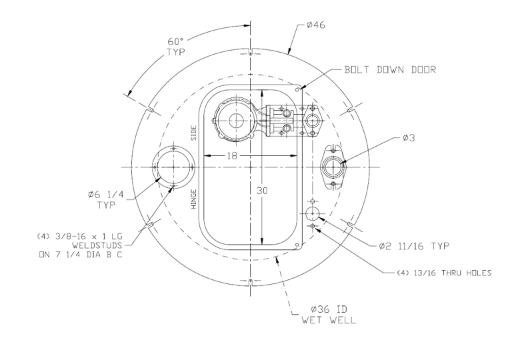

Figure 3 depicts a double walled basin cover which is custom designed to fit the outer basin, yet with penetrations to accommodate the dimensions of the equipment mounted in the inner basin. The bolted down access door will be positioned to allow access to the submersible pumps mounted in the inner basin.

Venting and float control wiring access must be located to allow access to the inner basin only. These locations are non-standard and must be coordinated with the basin cover manufacturer. Gastight sealant is used to prevent vapors from escaping the bolted down access door.