What is Dwell Time?

Submersible sewage or sump pumps are mounted inside a basin to remove liquid once it reaches a designated level in the basin. The pump is directed to start pumping by its control panel. The control panel receives signals from float switches to start a pump and pump out the pit, then stop the pump once the desired fluid volume has been removed. The elevation of the On (Start) float relative to the elevation of the Off (Stop) float will determine the volume of fluid to be removed.

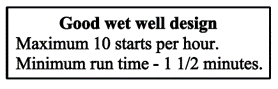

The volume of fluid to be removed should be large enough to meet the manufacturers “Minimum runtime” requirements also known as “dwell time” to avoid short cycling of the motor. If the pump motor is short cycled, then poor pump life may result. It is desirable to design the pit’s volume below the inlet elevation to allow 3 minutes of operation per cycle. Some submersible manufacturer’s pump models allow operating time as low a 2 minutes. If a submersible pump is rated to provide 100 GPM when activated, then it would be desirable to provide a volume of 300 gallons between the On (Start) and Off (Stop) float switches. If space is limited then volume of 150 gallons between the On (Start) and Off (Stop) float switches would be technically viable.

Calculating Dwell Time

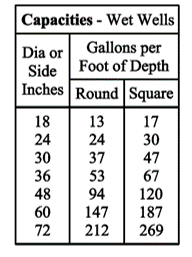

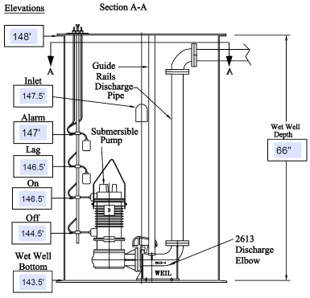

Figure 1 depicts a common duplex pit configuration. The floor, invert and float elevations are identified in feet while the wet well (basin) depth is identified in inches. In this example the distance between the On (Start) and Off (Stop) float switches is 146.5’ – 144.5’ = 2 feet or 24 inches. Referring to figure 2 which indicates wet well (basin) volumes per foot of depth. If the basin were 36 inches in diameter, then the volume between the float switches is 2 feet x 53 gallons = 106 gallons. If the pump capacity was 100 gpm, this volume would provide the minimum runtime of ~1.0 minute which is not recommended. However if the basin were 48 inches in diameter, then the volume between the float switches is 2 feet x 94 gallons = 188 gallons which would allow a runtime of about 1.9 minutes per cycle which meets the minimum runtime requirements.