Tech Talk – Why use a Hydrocumulator Tank?

Hydrocumulator tanks, also known as “expansion tanks”, are not required for proper operation of a booster system, so why would it be desirable to use one? Most booster systems are required to provide flow at 25% of peak design flow for 75% of their service life. During these periods of “leak loads” it is possible to allow the pumps to be completely shutdown if a volume of water is stored. Hydrocumulator tanks accomplish this by storing a volume of water which is based on its location and volume. The pump shut down will ultimately contribute to the life of your water booster.

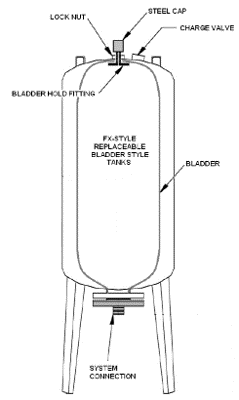

Hydrocumulator tanks consist of a metal tank fitted with a 65 Shore “A” butyl rubber bladder which separates water from the walls of the steel tank. Bladders provide an NSF & FDA listed material which provides low nitrogen/air permeability. Bladders are typically designed with a life expectancy of 50,000 cycles with a maximum design temperature of 240° F.

Booster system control logic can be designed to enable the lead pump to run to provide an additional 10 Psig to charge the hydrocumulator, then stop. Once the hydrocumulator is charged it supports leak loading until its charged volume is depleted.

Adjacent or Remote Location?

If we assume our system pressure is 150 Psig and we mount a 132 gallon hydrocumulator tank adjacently. We must precharge the tank with 150 Psig compressed air. The booster will “cut in” at 145 Psig and “cut out” at 160 Psig. Given these conditions the manufacturer advises the tank will provide 11 gallons to support leak loading. Since the system pressure is 150 Psig, a more expensive tank rated for higher pressure will be required.

If we assume our system pressure is 150 Psig and we mount a 132 gallon hydrocumulator tank remotely at the top of the building, and we desire to provide 40 Psig to the highest fixture, then our pre-charge pressure will be 40 Psig. Our “Cut In” pressure will be 35 Psig and our “Cut Out” pressure will be 50 Psig. The manufacturer advises the tank will provide 31 gallons to support leak loading. Since the fixture pressure is 40 Psig a less expensive tank rated to support a lower pressure will be viable.

Locating a hydrocumulator tank remotely can be less expensive, but always provides more leak loading volume.